“Why wait, Just Create” is a systematic and proven approach meant for companies who want to transform themselves from a service provider model to a product owner model. Before going into the details of this approach, it is appropriate to understand the two models, namely the service provider and the product owner. A service provider model is one of the most common business models.

It is typical of companies who focus on providing customized solutions to their clients. However, even a “generic service” like engineering automation or software development cannot encompass client requirements which can be very unique and specialized, ranging from diaper manufacturing to hard disk assembly! Therefore, service providers tend to target only the industry domains, clients and projects that their technical resources are comfortable to take on.

Unfortunately, this limits their scope of business development while exposing them to the risks of customer dependency and a frugal survival during economic downturns. A product owner model is not a common model as it involves investment of time, money and resources to develop and market products.

#1 DREAM: Ideation & Opportunity Assessment

We take a lot of things for granted in every aspect of our lives; especially commonly used every day items like tooth-paste and a ball-point pen. These came about ONLY because someone “dreamt” about it, questioned the obvious and then did something about it.Basically, all these were ideas that were developed into products! So in the first phase, one simply needs to be observant and question everything.

The Project Strategy document is not complete until a “Risk Analysis” has been conducted with the technical team, the marketing team, the finance team and the management team. There is only one question to ask, “What can go wrong and how can it be prevented or mitigated?”

#2 THINK: Information Gathering & Analysis

One of the most common causes of product failure is a lack of user input. So, we strongly believe that behind every successful product, there is a committed control group. It is important to create a control group from a set of potential users based on their experience, domain knowledge, user characteristics and enthusiasm.

It helps to incentivize them appropriately to garner their commitment for the success of the product. A committed control group provides the critical information required for the technical team to understand the user requirements and how the product will have a positive impact on them.

This definitely requires a certain amount of skill and patience as control group members usually provide information as and when they remember it. This information is diligently recorded and analysed by the technical team. It is important to verify the technical team analysis with the control group to clarify any mis-understanding. Usually, a significant amount of time is spent in this phase.

However, this is construed as time well-spent because the product development team now becomes knowledgeable with regards to the product functionality, user behaviour and needs, value added features for the product and other critical technical product specifications.

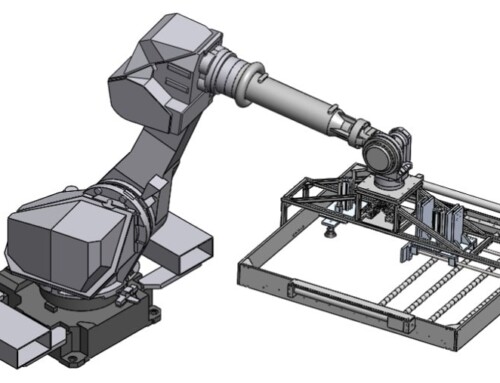

#3MAKE: Prototyping & Implementation

After studying and understanding the technical specifications, each team member should be able to visualize the final result of the product in one’s mind. However, this mental picture will be as different as each team member!It’s now time to covert themental pictures into something actual which everyone can“feel”. This could be in the form of mock-ups,a 3D model, sketches ora simple prototype.

Patience and Passion will ultimately transform the Cave-Man Model into a“Product Mock-up”. Good documentation practices help to consolidate and keep track of all the development activities once the Product Design is finalized.

These include detailed design documentation, technical calculations, process experiments, test data, operation, maintenance and real-time monitoring procedures,FAQs, Help Files, List of Spares, data back-up, etc.

The product also goes thru numerous testing processes to evaluate robustness and reliability. All the Quality Control data is documented and analysed for design changes, improvements, etc.

The above is only possible through good resource management. However, we believe that a motivated team does not need to be managed but only guided and encouraged. In fact, motivated teams tend to show a drop in performance when they are micro-managed. As such, we encourage empowerment of project teams and allow them to take technical & project-related decisions. Managers need to involve only in case of conflict resolution or when the team decides to bring them in as and when required. Only managers who show their involvement without authority will be able to work successfully with such teams.

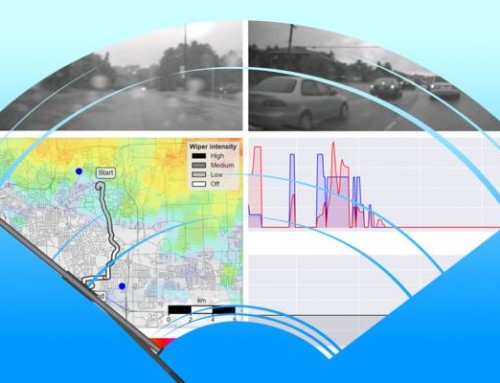

#4SUSTAIN: Continual Improvement&New Technology Adoption

All products are designed with built-in monitoring and data analytics features to provide a real-time feedback on product performance. This is usually done over wired or wireless networks, mobile data and the cloud. In addition to this, regular surveys, meeting and feedback from the users is very helpful to plan improvement activities to give the user a better experience.